April 1, 2015 — UHC has released the findings of a new study that evaluated the use of medical devices based on cost and quality outcomes. The goal of the study was to uncover several trends related to high-priced physician preference items (PPIs). Utilization of PPIs — which can account for 30 to 40 percent of a hospital's supply expenses — at 10 academic medical centers, focusing on procedures utilizing orthopedic implants, coronary and peripheral stents and cardiac valves.

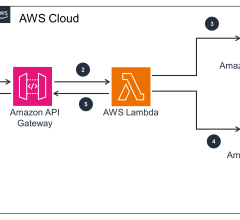

The study, begun in 2013, integrated the pilot test of the UHC Supply Cost & Quality Tool, a business intelligence tool designed to help healthcare organizations identify variations in the use of medical devices and their links to costs and patient outcomes. The study identified the following trends:

- "Custom" does not always mean quality: One organization identified a surgeon who routinely used a customized hip implant for patients undergoing standard, elective total hip replacement. The price tag for the customized implant alone was higher than the average Medicare reimbursement for the entire hospital stay. This physician's patients also had longer hospital stays, on average, and higher readmission rates than those of other physicians.

- Hidden waste in unused devices: An analysis at one hospital showed that one of its physicians was wasting an average of $600 per hip implant procedure—six times more than other physicians at the hospital—as a result of opened but unused implants.

- Not all devices match every patient: At one organization, physicians were consistently using hip implant components for older patients that were more advanced than those used for younger patients, counter to published research showing that standard components are more clinically appropriate for less-active patients. The costs of the advanced components were usually at least 25 percent higher than those of standard components.

"Our study reinforces that there is a clear need for healthcare organizations to have an integrated view of supply costs and patient outcomes in resource-intensive areas, such as orthopedic and cardiovascular care," said Mike Oinonen, senior director, CDI operations, product technology, UHC. "By leveraging data from UHC's supply chain and clinical databases, along with utilization data from their clinical systems, the study participants identified significant opportunities to reduce clinical variation, strengthen contract negotiations with suppliers, improve product selection and minimize product waste."

Following the pilot project, UHC released the Supply Cost & Quality Tool to its membership; UHC members that subscribe to the Clinical Data Base/Resource Manager and SpendLINK are eligible to participate in the tool.

The case examples in the paper were derived from a very limited data sample from organizations that participated in the Supply Cost & Quality Tool pilot project. UHC plans to develop benchmark data while expanding into additional clinical areas as more participants use the tool.

For more information: www.uhc.edu

July 30, 2024

July 30, 2024