December 29, 2021 — Researchers at the University of Surrey have identified key design rules for making curved X-ray detectors, bringing clearer and safer X-rays a step closer to reality.

Although the use of digital flat panel detectors has enabled radiographers to examine X-rays much more quickly compared with old-fashioned X-ray sensitive photographic films and to make quicker diagnoses, flat panels are ill-suited to the complex shape and geometry of the human body. The reliance purely on flat panels means there is unavoidable distortion around the edges of images. Flat panels also prevent an accurate registration of the X-ray dose delivered, a key feature towards enabling safer radiation therapy and minimizing secondary tumors.

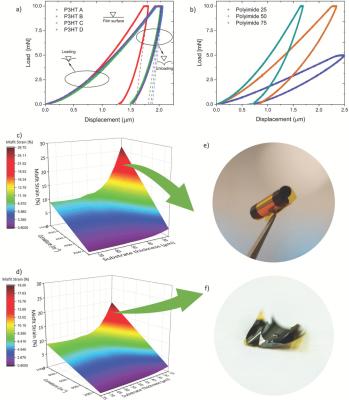

Efforts to create flexible detectors have so far been unsuccessful owing to the brittle characteristics of the rigid inorganic semiconductors used to make them. Some curvature has been achieved through using a thinner layer of semiconductor, but this has compromised performance levels and resulted in poor quality images.

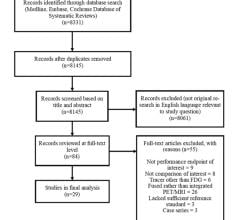

However, in a study published in the peer-reviewed journal Advanced Science, researchers from the Advanced Technology Institute at the University of Surrey, in collaboration with Italy’s University of Bologna, the National Physical Laboratory and Sheffield University, identify design rules for a special class of “inorganic in organic” semiconductors. By tuning the molecular weight of the bismuth oxide nanoparticle sensitised organic semiconductors to lengthen the polymer chains, the researchers are paving the way towards making more robust, curved digital detectors with high sensitivity, or digital film.

Prabodhi Nanayakkara, lead author of the study and PhD student at the University of Surrey, said:

“Our curved detector concept has shown exceptional mechanical robustness and enables bending radii as small as 1.3mm. The use of organic or ‘inorganic in organic’ semiconductors is also far more cost effective than conventional inorganic semiconductors made from silicon or germanium, which require expensive crystal growth methods. Our approach potentially offers a significant commercial advantage.”

Professor Ravi Silva, Director of Surrey’s Advanced Technology Institute, said:

“The technology we’re demonstrating will help create a revolutionary new high sensitivity X-ray detector that is scalable, due to the design and materials adopted. This technology has huge potential in medical applications and other X-ray uses, so we’re working with a spinout company, SilverRay, and hope to turn this technology into the X-ray detector of choice for high sensitivity, high resolution, flexible large area detectors.”

For more information: www.surrey.ac.uk/

March 19, 2025

March 19, 2025