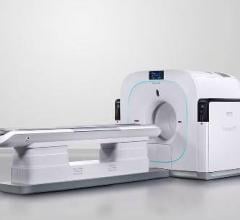

April 20, 2012 — GE Healthcare and NXT2B, a privately owned venture capital company, announced they have entered into a joint financing agreement with the goal of developing a micro-scale radiotracer infrastructure including cyclotron and positron emission tomography (PET) tracer production. The three-year development project will be led by GE Healthcare and will be headquartered in Uppsala, Sweden. The terms of the agreement were not disclosed.

“In line with GE’s Healthymagination strategy to develop innovations that increase access, reduce cost and improve quality in the healthcare system globally, GE Healthcare and NXT2B are pleased to announce a joint financing project to develop an unmatched next generation of equipment and software for the production of PET tracers,” said Erik Strömqvist, general manager, cyclotrons, GE Healthcare. “The goal of the project is to develop a turn-key radiotracer infrastructure solution for the production of PET tracers to primarily fulfill the needs of emerging markets, for rural and regional hospitals, and researchers.”

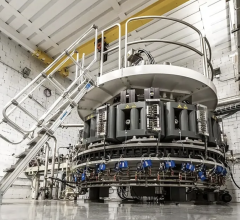

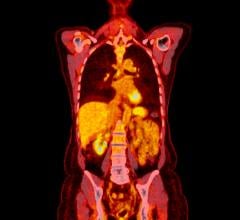

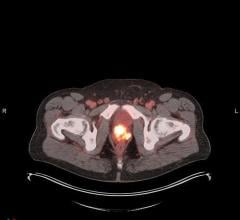

At the core of the new TRACERcenter 600 are a compact, cost-effective, easy-to-site cyclotron and a radiotracer production operation. The PETtrace 600 cyclotron will have an approximately 50 percent smaller footprint than a traditional cyclotron, enabling siting in settings never before possible. Together with PETtrace 600, the TRACERcenter 600 solution will be capable of producing a full portfolio of F18 and C11 tracers to detect cancer and neurodegenerative disease.

“We’re proud to partner with GE to help create greater access to PET tracer production in areas of the world that previously did not have access, and to address the large unmet needs for PET diagnostics in oncology and neurology,” said Bengt Ågerup, CEO and founder of NXT2B.

While the technology of PET scanners have rapidly developed and evolved, parallel advancements in the necessary tracer production equipment and processes have not occurred. Current PET tracer production methods are costly, complicated and require a large number of highly trained individuals. With the inherent nature of the short-lived isotopes, distribution is often not possible due to lack of supporting infrastructure in regions where PET imaging is expanding.

“Simplifying the process and technology of PET tracer production involves a paradigm shift from a traditional approach to a small, easy-to-use cyclotron, a chemistry module that is automated, and a complete and compliant quality control process that is integrated into the system,” added Stromqvist.

For more information: www.nxt2b.com, www.gehealthcare.com

July 30, 2024

July 30, 2024