January 16, 2018 — Researchers from the NUST MISIS Engineering Center for Industrial Technologies in Russia have developed an innovative technology for the production of magnetic materials and permanent magnets at a reduced cost. This engineering solution will allow scientists to produce affordable and efficient domestic magnetic resonance imaging (MRI) devices for wide use in public health clinics. According to the developers' estimates, the cost of an analysis with the new MRI technology will be half of what it is now.

MRI is one of the most effective diagnostic methods in modern medicine. The diagnosis of cancer, multiple sclerosis and musculoskeletal diseases in their early stages are all done with the help of MRI machines. The average cost of one analyses with the use of MRI costs between 4,000 and 12,000 Rubles, depending on the body part being scanned and the clinic.

Due to its technical nature, an MRI machine can have ultraweak, weak, medium, strong and superstrong magnetic fields. The highest-quality pictures are taken by using superconducting magnetic systems generating very strong magnetic fields. However, MRI machines based on superconducting magnets provide the highest image resolution, although these machines are difficult to make and more importantly, expensive to operate. That is why the procedures are generally inaccessible to most patients, because it is simply too expensive for the clinic or hospital to use the machine.

When considering the savings gained from using the new MRI machines, the researchers say most small clinics and private-practice doctors will prefer these cheaper, low-field MRI machines, which cover the overwhelming majority of most common diagnostic tests. Large hospitals, especially those interested in local spectroscopy and research in the field of functional tomography, will retain their interest in machines with stronger magnetic fields, but they will also buy scanners with weak and medium-sized fields as second and third installations for mass screening, according to the research team.

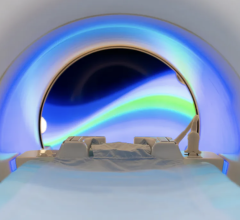

NUST MISIS scientists, jointly with their industrial partners from the Research and Production Association "Magneton," have developed a prototype of an economically and environmentally-friendly low field magnetic resonance imaging prototype based on magnetic materials and components produced in Russia.

"We have developed an innovative technology for the production of low-cost hard-magnetic materials and permanent magnets manufactured from alloys of rare, domestic earth metals and their compounds, including the ones obtained in the processing of industrial waste magnetic production. During the production of raw materials for permanent magnets we have managed to reduce their cost by 1.5 times through the use of industrial waste magnetic production and cheap alloys of rare earth metals. The use of new soft magnetic materials has allowed us to develop magnetic conductors for a magnetic system of the scanner with low loss while maintaining high values of magnetization saturation (more than 2 T). All this allowed us to design and reduce the weight of permanent magnets used in the design of magnetic systems by almost 30 percent, and thus to reduce the cost of the devices," said Evgeny Gorelikov, the project head, Candidate of Political Sciences, and deputy director of the NUST MISIS Engineering Center for Industrial Technologies.

The cryogenic technology, liquid nitrogen, helium fluid and water for cooling (as in the case of MRI using superconducting magnets or electromagnets) are not required to run the new MRI machine. The power consumption of this scanner will be less than 1 kW, hence why it may be possible to power it even with renewable energy sources such as solar panels and wind turbines.

Currently, the Russian and foreign analogs of this newly developed magnetic system cost almost twice as much to implement into the medical field.

Given the fact that China is currently the world's main producer of rare earth metals and rare-earth permanent magnets (up to 80 percent), the use of domestic magnetic components gathered in the production of MRI machines allows Russia to create production that is independent from imports.

The project's implementation will provide a practical opportunity to create a competitive industrial production of magnetic materials with reduced cost and a personal base for the autonomous production of a new generation of low-field magnetic MRI machines in Russia.

For more information: www.en.misis.ru

July 25, 2024

July 25, 2024