October 13, 2016 — At the 58th annual meeting of the American Society for Radiation Oncology (ASTRO), Orfit Industries presented the new generation of nano-based masks.

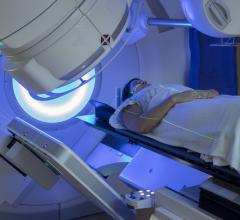

Compared to Efficast masks used for head and neck immobilization, immobilization masks made from nano-enhanced thermoplastic sheets provide the patient with more comfort through a lower degree of shrinkage, and therefore reduced pressure on the face during radiation therapy. The issue of mask tightness is a very common one, as medication received during the radiation treatment phase may result in an increase in the volume of the patient.

In its efforts to provide a higher degree of patient comfort, Orfit Industries developed a nano-based thermoplastic material that results in thinner masks with less shrinkage. Orfit engineers have interwoven a natural material (nano clay) in the inner layers of the thermoplastic material, which resulted in a substantial improvement of its mechanical properties. Thermoplastics will shrink when they cool on the patient during the mask making process and therefore have an impact on comfort, in particular when the volume of the patient tends to increase in the course of treatment. In this context, the reduction of shrinkage by means of NANOR is an important step forward as it provides the degree of comfort required to minimize patient movement during the delivery of the dose.

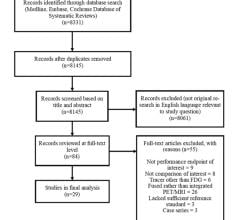

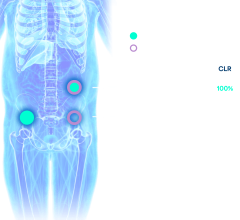

In a number of laboratory tests, the Orfit research team compared two low melting temperature thermoplastic materials, known under their commercial names NANOR and Efficast, both developed and manufactured by Orfit Industries. The results show a reduction of fixation force for NANOR, making patient immobilization easier and contributing to patient comfort and ultimately effectiveness of radiation therapy.

The Orfit tests also revealed that nano-reinforced thermoplastics have a higher bending modulus, i.e. the force for bending or deforming the material. The bending modulus of NANOR sheets is about two times higher than the bending modulus of Efficast sheets. Using NANOR allows for a reduction of the thickness of the immobilization masks to 1.2 and 1.6 mm instead of 2 and 3.2mm of Efficast, for identical mechanical properties of the immobilization mask. This in turn increases the patient’s comfort as the material conforms better to the anatomy.

The company has received U.S. Food and Drug Administration (FDA) clearance for its use of NANOR thermoplastic technology as of 2014.

For more information: www.orfit.com

August 09, 2024

August 09, 2024